Chances are your roll does not need to be re-engraved or replaced, just professionally cleaned by one of our service technicians. Our clients typically save up to 75% when using our services versus typical re-engraving costs. We can clean your rolls either ON-PRESS at your facility, a level of service no one else offers, or OFF-PRESS. Clients also can choose to ship their rolls to our Factory for cleaning. Our method is proven, safe on all roll surfaces, and very environmentally friendly & can provide unlimited client references upon request. We are also a USA distributor of Capatch Volume Test Strips for various types of rolls. These strips allow you to instantly test your roll volume (BCM), and quickly assess whether or not your roll is operating at its optimal level.

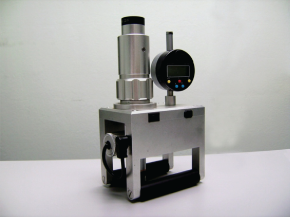

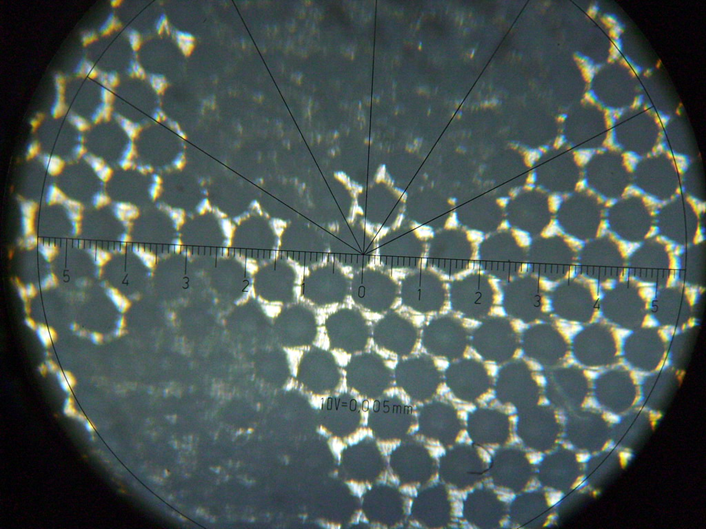

Cell Check tools.

Before

After

The CAPATCH Tools

The Purpose

- The Capatch is a "cell pollution trend watcher" and a quick method for measuring volumes of Anilox and Gravure full coating rolls in printing presses. The Capatch has a tolerance of plus or minus 10 percent. Although it might have a similar tolerance to other measurement instruments such as Wyco, Urmi, Ravol and Volugraph, it is not meant to replace them. These methods take 10 to 15 minutes, or longer, to carry out. The Capatch is an additional tool for use in the printing press and gives a rapid reading but with a slightly larger tolerance. It takes no more than two minutes to apply the Capatch correctly.

In the printing industry, regularly testing the volume of your anilox or full coating gravure roll is crucial for preventing production losses. Wear, "doctoring", improper cleaning can cause incorrect volumes. Don't assume that your roll has the correct cell volume. Use Capatch to:

–Obtain an indication of the volume of your roll

–Reduce production stops to five minutes or less

–Prevent scrap production

–Provide a verification of the volume of a roll after cleaning or maintenance

This depends on the type of production: frequent changes of production and colors increase the likelihood that the cells will become plugged. Some printers check their rolls with Capatch every two weeks. On each roll they use at least two Capatch strips. In case of a large difference between the two results, they use a third Capatch strip for confirmation.

On Site Cleaning

This service offering is completely turn-key. Your rolls stay in your press and we do all the work. We work around your downtime either during the week or on the weekend.

Please contact us for a quote -- we just need to know the length and diameter of your rolls.

Off-site Cleaning

Many of our clients choose to have their rolls cleaned Off-press, which we can do either at their facility or ours. When done at the client facility, we bring a special roll cart that holds the roll in place during the cleaning process.